NanoSoft Autogrid Inspection Tool

The autogrid inspection tool is a low-cost way of performing a last autogrid inspection step prior to loading them into the cassette.

High demand for cryo-EM imaging time at core facilities has resulted in ever-growing throughput of samples through high-end, autoloader-based EM’s. Often the person loading autogrids into the autoloader cassette did not clip the grids that they are loading. Inserting a poorly clipped autogrid into the cassette could lead to it popping out of the cassette while in the autoloader and significant EM downtime.

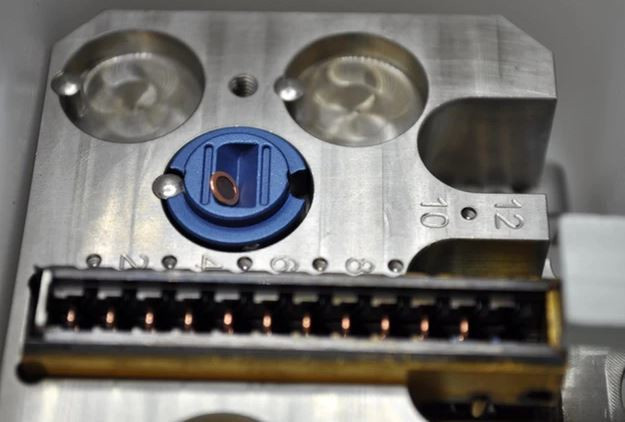

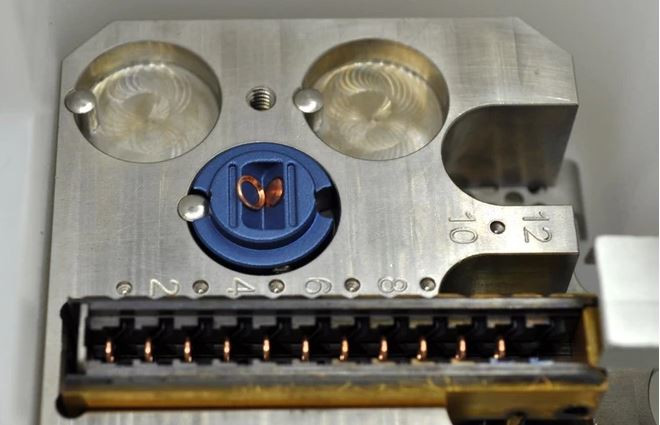

How it works, the autogrid inspection tool is placed into a grid button spot in the cassette loading station and will remain there securely indefinitely due to the spring-loaded detent on the side of the tool. Autogrids can be placed in the groove of the Autogrid inspection tool and quickly flipped back and forth to check that the grid is securely clipped. It provides a final, low-cost check to help ensure only well-clipped grids are loaded into the autoloader, saving the potential disaster of a poorly clipped grid coming undone in the autoloader and weeks of downtime.

The anodized aluminum part fits into the grid button spots in the aluminum part of the FEI/Thermo Fisher cassette loading station and allows to check and ensure the grid was clipped correctly prior to loading into the cassette.