Lab Spotlight:

XChem Lab - Diamond Light Source

An accessible, fast and high-throughput fragment screening facility to accelerate drug discovery.

"In 2017, we welcomed more than 30 XChem industrial and academic projects through the pipeline. More than 30,000 crystals were mounted using MiTeGen products and screened on the I04-1 beamline."

Fragment-based drug discovery is an established technique of two decades ago. Industry and academia have widely adopted this approach, whereby several hundreds of low molecular weight (200-300 Da) chemical entities are screened by a biophysical method against the protein of interest. The hits from a fragment screening campaign are usually of low affinity but they offer wide possibilities of chemical elaboration and therefore can be interesting starting points for drug discovery programs.

X-ray protein crystallography is a very sensitive detection method and provides structural information to atomic details of the interactions between the protein and its ligands. Modern synchrotrons are equipped with top-edge technology such as fast detectors, fast and reliable robotics and powerful computing infrastructures, which altogether have massively increased the production of X-ray protein crystallography structures.

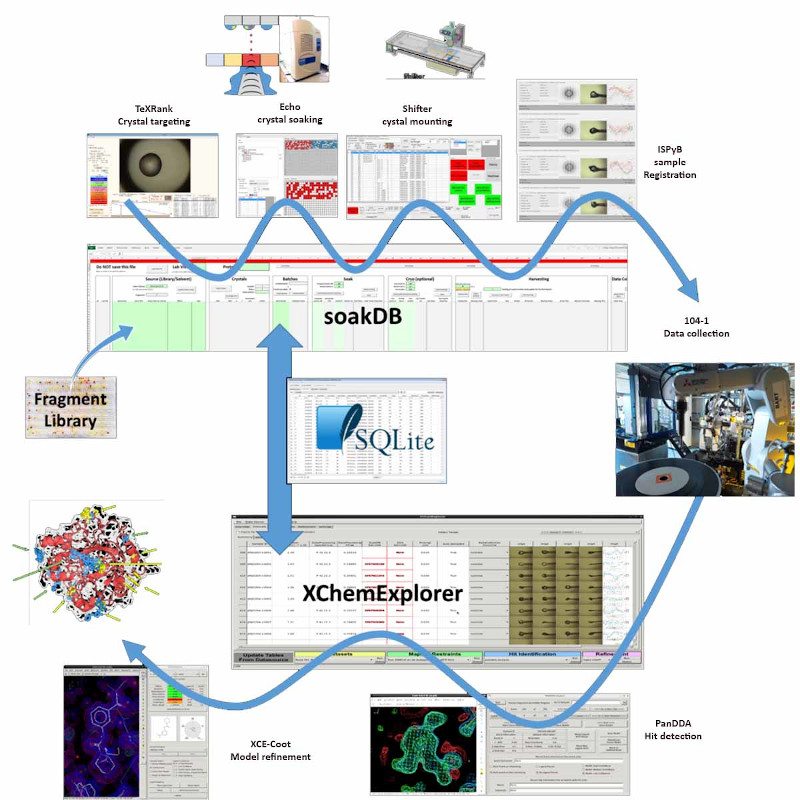

The bottleneck of high-throughput preparation of soaked samples has historically hindered the use of X-ray crystallography as a primary screen. At Diamond Light Source, the team around beamline I04-1 partnered with the Structure Genomic Consortium (SGC) at Oxford University, to set up the XChem's facility, which covers from the quick preparation of samples down to data collection and data analysis. XChem fully integrated laboratory allows users to prepare their hundreds of samples rapidly and efficiently. The laboratory is equipped with an acoustic liquid handling ECHO (Labcyte) for high-throughput fragment soaking (Collins P. M. et al), and a fast crystal shifter device (Oxford Lab Technologies Ltd.) for efficient crystal harvesting. Users are also provided with size-sorted pins from MiTeGen to match the harvesting loops to the crystals, essential for high-throughput unattended data collection on the adjacent fixed-wavelength beamline I04-1. Several fragment libraries either optimized for rapid follow-up chemistry (DSI-poised, Enamine, Cox. O. B. et al ) or for 3-dimensional properties (Leeds-3D, Foley D. J. et al.) are available to users. The high density of data is managed through a SQLite database XChemExplorer (Krojer T. et al.) which integrates PanDDA, a density modification algorithm for identifying weak binders (Pearce N.M. et al.).

Since April 2015, Diamond Light Source has offered its fragment screening platform as part of its user program. In 2017 only, we welcomed more than 30 XChem industrial and academic projects through the pipeline. More than 30,000 crystals were mounted using MiTeGen products and screened on the I04-1 beamline.

For information regarding the fragment screening platform at Diamond Light Source Ltd and how to access it, please visit:

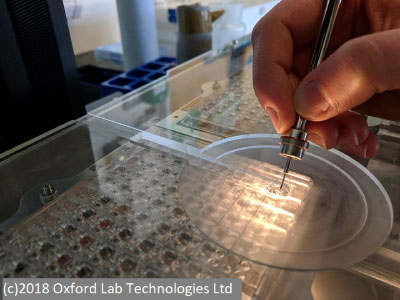

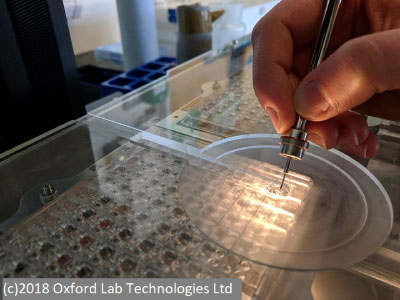

Crystal mounting is done using the Crystal Shifter Device (Oxford Lab Technologies Ltd.) to quickly translate desired plate wells to the harvesting location.

Illustrating the pipeline at XChem

Contact:

Frank von Delft

Principal Beamline Scientist

frank.von-delft@diamond.ac.uk

XChem Page

References:

Collins P. M. et al. Acta Cryst. (2017). D73, 246-255

Cox O.B. et al. Chem. Sci. (2016). 7, 2322-2330

Foley D. J. et al. Chemistry. (2017) 23(60):15227-15232

Krojer T. et al. Acta Cryst. (2017). D73, 267-278

Pearce N.M. et al. Nat Commun. (2017). 8, 15123

Recommended MiTeGen Tools

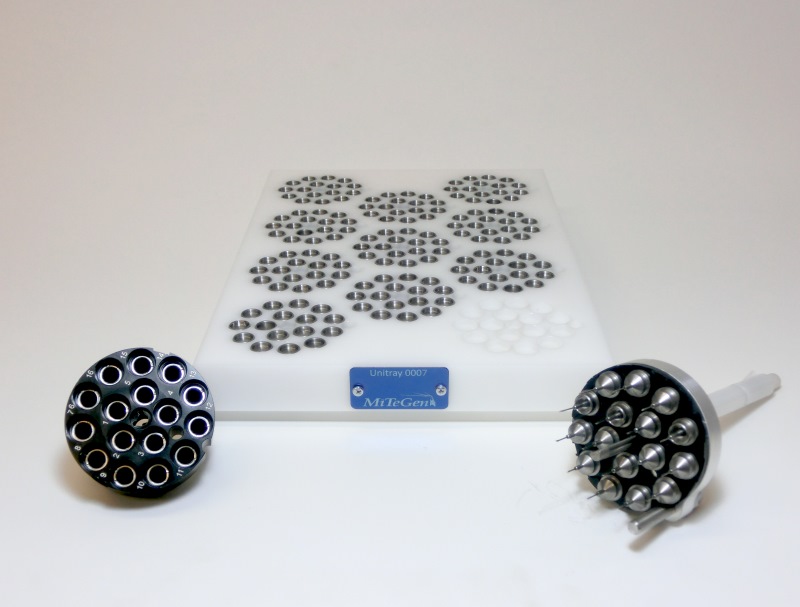

The Unitray™ system was developed in a collaboration between the XChem Facility and MiTeGen. At XChem, Unitrays loaded with MiTeGen MicroLoops LD™ and reusable bases are used routinely to enable improved crystal harvesting through loop organization and rapid loop cleaning.

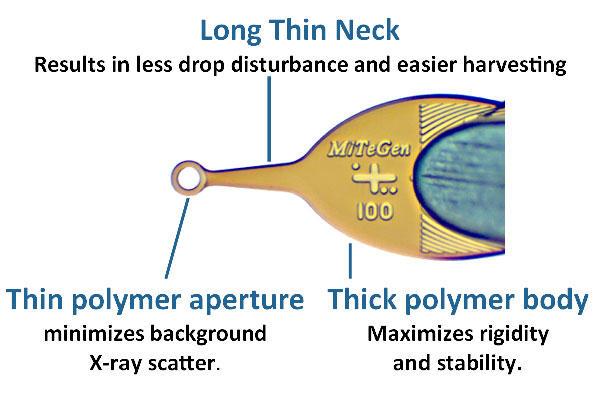

Dual-Thickness MicroLoops LD™

A loop that provides simplified harvesting, improved cryocooling, lower background and easier auto-centering. The standard loop for crystal harvesting at XChem.

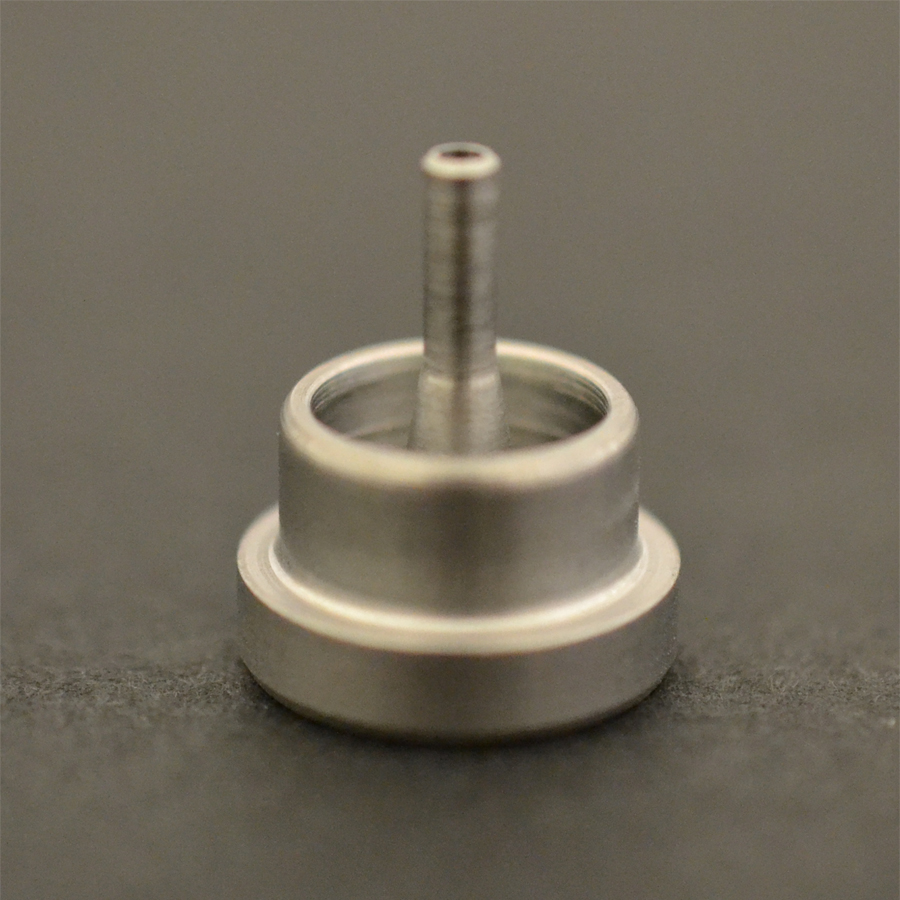

Reusable SPINE Bases (B5-R)

A loop that provides simplified harvesting, improved cryocooling, lower background and easier auto-centering. The standard loop for crystal harvesting at XChem.

Crystal Shifter

A Platform to Improve Your Experiment Quality and Velocity

Diamond Light Source XChem lab had a challenge to solve: how to improve experiment quality and at the same time increase the throughput of its crystallography so more labs can use their beamlines. This had to be done on a very tight budget too. The solution was the Shifter platform: device and software that helped Diamond's customers pick more than 70,000 crystals whilst continually improving quality of experiments.

Crystal Shifter platform consists of a x-y microscope stage device and software that automates experiments and integrates with other systems. The device can move 2 plates (typically SwissCI 96 well plate or other plates with same dimensions) across the stage and to various locations to enable different experiment protocols. The protocol and work lists are defined in the software. Any location on both plates can be placed under a microscope or another position on the device. The software iterates the worklist, presenting desired wells below the microscope (or another desired location) where a crystal (or another sample) can be picked and mounted into a destination, typically a puck). The software is operated using a large touch screen so the operator's attention can be on picking and mounting crystals.

By using such an automated process, at Diamond Light Source, an improvement of experiment quality has been observed as the operator can now limit her movement and focus on how crystals are picked. At Diamond Light Source we have also observed significant increase of experiment velocity (throughput) as previously manual operations are now automated and the operator is performing a repetitive activity (picking/mounting). A novice user was trained at Diamond in matter of hours to be able to pick up to thousand crystals a day.

Whilst Shifter demonstrated experiment quality and throughput improvements at Diamond there are other benefits this platform brings. For example, the software keeps full audit trail of experiment, assigns crystal IDs automatically, and captures destination (puck) locations too. It can fully integrate with variety of tools and systems and has out-of-the-box integration with SoakDB.

The Shifter platform roadmap includes imaging capability and integration with pipetting robots. This functionality will provide an inexpensive alternative for crystal imaging and soaking.

To learn more about Crystal Shifter and see it in action, please visit: