GloQube Plus Glow Discharge System for TEM Grids

The GloQube™ Plus is the first-of-its-kind compact, easy to use, stand-alone glow discharge system.

The primary application of the GloQube™ Plus is the hydrophilization (wetting) of carbon-coated TEM support films and grids which otherwise have the tendency to be hydrophobic. Glow discharge treatment with air will make film surfaces negatively charged and hydrophilic and allow the easy spread of aqueous solutions. This and other processes are outlined below.

For a limited time, we offer a special discount on the GloQube™ Plus. Request your quote below before it’s too late.

The GloQube™ Plus requires a single vacuum pump working in the 0.1 to 1 mbar range. See the Accessories Tab below for recommended vacuum and other accessories

Product Information

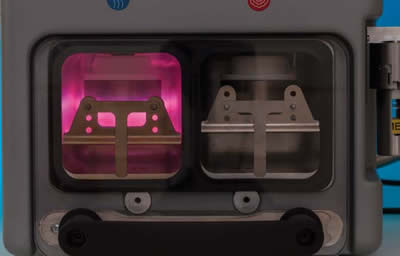

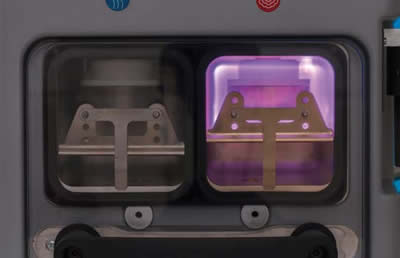

Unique Dual Chamber Processing, Safe Handling of Reagents

The GloQube Plus has two independent vacuum chambers: a clean chamber, designed for applications requiring hydrophobic/hydrophilic conversion, typically using air as the process gas; and a vapor chamber, designed for use with reagents such as methanol and alkylamine. With operator safety firmly in mind, reusable septum-sealed reagent vials are used. Loading and removing reagents is convenient and reliable – the vial, located in its holder, is inserted into a shielded needle using a simple bayonet fitting.

To prevent accidental damage, the high voltage lead is shielded. The plasma current is variable by adjustment of the vacuum level using an argon leak valve with the plasma voltage being preset. For maximum sputter coating efficiency, the gas injector system ensures that argon gas enters the chamber close to the plasma discharge. Venting is to argon.

Key Features

- Dual independent chambers

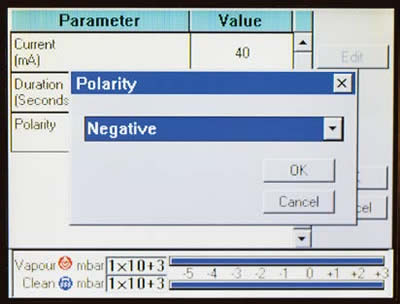

- Hydrophilic/hydrophobic and negative/positive modes

- Fully automatic, short process times

- Intuitive touch screen control

- Safe vapor delivery using septum-sealed vials

- Automatic valving between chambers to prevent cross-contamination

- Quick and easy sample loading

- Controlled venting to prevent sample disturbance

- Consistent, reliable results

- Three-year warranty

The primary application of the GloQube™ Plus is the hydrophilization (wetting) of carbon-coated TEM support films and grids which otherwise have the tendency to be hydrophobic. Glow discharge treatment with air will make film surfaces negatively charged and hydrophilic and allow the easy spread of aqueous solutions. This and other processes are outlined below.

| Glow Discharge Process | |||

| Surface State | Charge | Atmosphere | Typical applications |

| Hydrophilic | Negative | Air | Carbon coated TEM grids |

| Hydrophilic | Positive | Air – with magnesium acetate post-treatment | Nucleic acid adhesion to carbon films |

| Hydrophilic | Positive | Alkylamine | Proteins, antibodies and nucleic acids |

| Hydrophilic | Negative | Methanol | Positively charged protein molecules (e.g. ferritin, cytochrome c) |

Easy sample loading, fast turnaround times

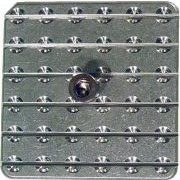

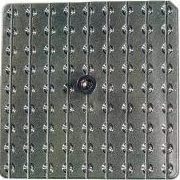

Each chamber can accommodate two 25 x 75 mm glass microscopes slides. Loading could not be easier using draw-style chamber doors and specimen stages. The stages are height adjustable and fitted with removable glass slide holders. For additional convenience – and to allow easy access for chamber cleaning – the stages can be completely removed.

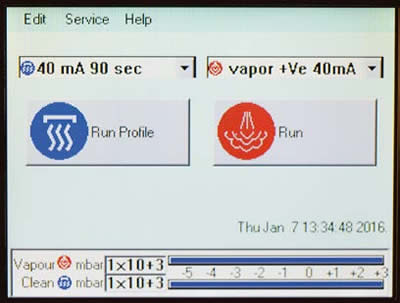

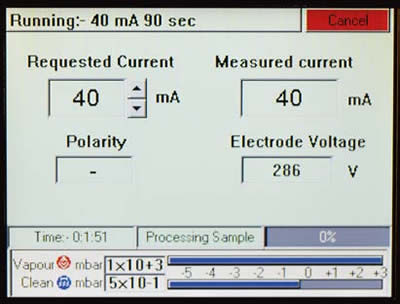

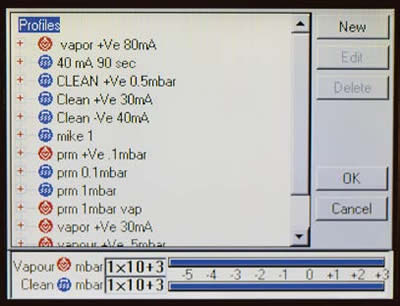

Touch screen control – rapid data input, simple operation

The intuitive touch screen allows multiple users to rapidly input and store preferred process "recipes". Typical default glow discharge protocols are loaded as standard. Additionally, help files and useful maintenance data such as system on time and time since last clean are readily available to the operator. An Ethernet communications port is included for software updates.

Vacuum, automatic valving and controlled venting

The GloQube™ Plus has automatic valving between chambers which maintains cleanliness by preventing cross-contamination. At the end of a process run, automatic soft venting to atmosphere through filtered inlets ensures TEM grids are not disturbed. The GloQube™ Plus requires a single vacuum pump working in the 0.1 to 1 mbar range. (See accessories tab for recommended pump) A typical pump time to operational vacuum is 60 seconds.

You may also like…

-

MiniQ GD Glow Discharge System

Designed with simplicity in mind, the easy-to-use MiniQ GD allows for surface modification of TEM grids....